What is Dot Matrix Printing technology

Dot matrix printing technology, also known as impact matrix printing, is a computer printing process that applies ink to a surface using a low-resolution dot matrix for layout. Dot matrix printers, like typewriters and line printers, use a print head that moves back and forth or up and down on the page and prints by impact, striking an ink-soaked cloth ribbon against the paper. A dot matrix printer, on the other hand, can print arbitrary patterns rather than just specific characters.

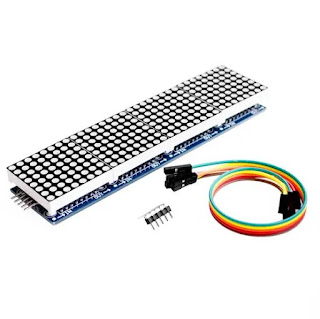

The perceived quality of dot matrix printers is determined by the printer's vertical and horizontal resolution as well as its ability to overlap adjacent dots. The most common are 9-pin and 24-pin connectors, which specify the number of pins in a specific vertically aligned space. Horizontal movement on 24-pin printers can slightly overlap dots, producing visually superior output (near letter quality or NLQ), usually at the expense of speed.

Dot matrix printing differs from non-impact methods such as inkjet, thermal, or laser printing, though they may also use a bitmap to represent the printed work. It can also print indefinitely using continuous paper fanfolded with perforations to allow each page to be easily torn from the next.

Printing Variation

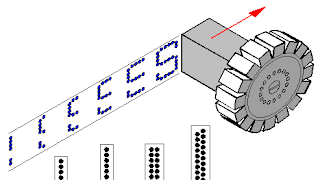

A horizontally moving print head is used in most serial dot matrix printers. Consider the print head to be a single vertical column of seven or more pins about the height of a character box. In reality, the pins are arranged in up to four slightly displaced vertical or horizontal columns to increase dot density and print speed through interleaving without causing the pins to jam. As a result, while the print head moves horizontally, up to 48 pins can be used to form the characters of a line. Serial dot matrix printers with moving heads have printing speeds ranging from 30 to 1550 cps.

Line dot matrix printers use a fixed print head almost as wide as the paper path to print a horizontal line of thousands of pins in a significantly different configuration. Interleaving two horizontally slightly displaced rows can sometimes improve the effective dot density. While still line-oriented, these printers for the professional heavy-duty market print an entire line at once as the paper moves forward beneath the print head. Line matrix printers can print much faster than 1000 cps, resulting in a throughput of up to 800 pages per hour.

The cross hammer dot printer, patented by Seikosha in 1982, was a variation on the dot matrix printer. A spinning, fluted cylinder replaced a conventional printer's smooth cylindrical roller. The print head was a simple hammer with a vertically projecting edge that was powered by an electromagnet. A single dot was marked on the paper where the vertical edge of the hammer intersected the horizontal flute of the cylinder, compressing the paper and ribbon between them. Characters were created by connecting multiple dots.