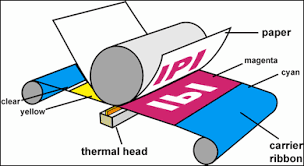

Dye sublimation is a printing technology that employs a specially designed ribbon that contains solid inks. The printer heats the ink, causing it to sublimate, which means it skips the liquid phase and goes straight to the gaseous state. (Another application of sublimation in the industry is freeze-drying.)

The page or other material is colored in three primary colors. When the ink hits the media, it changes from a gas to a solid, resulting in a full-color image. To prevent smudging of the ink, the printer applies a clear protective coating to the paper/substrate.

What is dye sublimation printing technology?

While the preceding information provides a better understanding of the fundamentals, let us delve a little deeper into the concept of transfer paper. These printers typically use transfer paper, but direct-to-fabric printing is also possible. The process is slightly more complicated if you use transfer printing.

When using a dye-sublimation printer to create transfer projects:

- Solidified ink will be applied to the transfer paper.

- The paper is heated with a heat press.

- Sublimation occurs, and the solid ink turns into a gas.

- As the gas permeates the fibers of plastic or synthetic fabric, an incredible image begins to emerge.

It again helps to contrast a standard inkjet printer to a dye-sublimation printer. In the former, liquid ink within cartridges becomes solid via heat and air as it dries on the paper’s surface. The two-step dye sublimation printer process involves liquid ink being introduced to media, where it dries and becomes solid, followed by vaporization (sublimation, in this case) of the solid ink.

Dye-Sublimation Printing Technology (or dye-sub printing) is a digital computer printing technology that transfers dye onto materials such as plastic, card, paper, or fabric using heat. The term "sublimation" was coined because the dye was thought to transition between solid and gas states without passing through a liquid stage. This understanding of the process was later proven to be incorrect, as the dye liquefies. Since then, the process has been referred to as dye-diffusion, though this technically correct term has not replaced the original name. Many dye-sublimation printers, both consumer and professional, are designed and used to produce photographic prints, ID cards, clothing, and other items.

These should not be confused with 'dye sublimation heat transfer imprinting printers,' which are inkjet printers that use special inks to create transfers designed to be imprinted on textiles and in which the dyes actually sublimate. These are carried out at lower temperatures but higher pressures, especially in all-over print processes.

Text and bar codes are required for ID card printing, and they are printed on an additional black panel on the (YMCKO) ribbon. Instead of dye diffusion, this extra panel works by thermal transfer printing: a whole layer, rather than just some of the dye in the layer, transfers from the ribbon to the substrate at the pixels defined by the thermal head. This overall process is sometimes referred to as dye diffusion thermal transfer (D2T2).